Safety based on Simplicity, Common sense and Human instinct

Fire-proof, designed for time-critical panic-situations. Based on simplicity, common sense and human instinct.

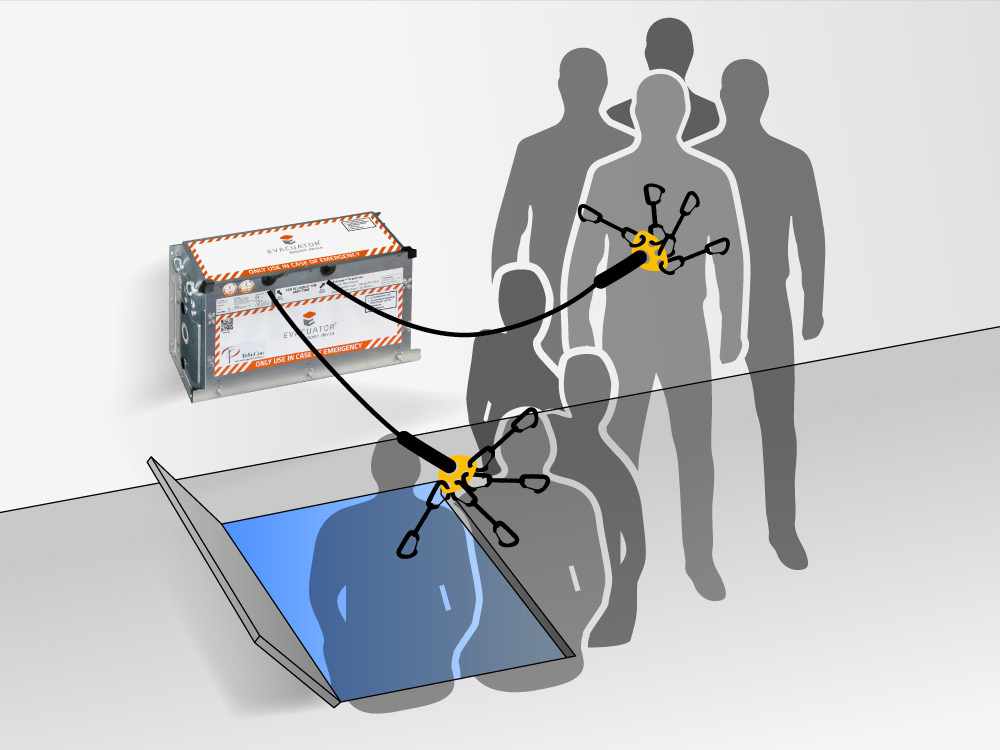

Escape hooks

No time consuming preparations due to pre-installed and fixed installed escape hook at the emergency escape hatches, always there where you need it, immediately ready to use.

Steps to be ready

In 3 steps ready for the escape descent. Simplicity is key. The escape with the Evacuator® escape descent system does not require any time-consuming actions.

people at once

Up to 8 people can descent, the total maximum descent load on the system is 564 Kg at the same time. The maximum descent load per cable-reel is 282 Kg.

Seconds ready

The escape-procedure is ‘just click on and go’. Within 10 seconds the persons are ready to start their escape descent.

Years lifespan

The Evacuator® is installed for the lifetime of 30 years, and even more. As every safety system in the wind turbine, the Evacuator® is also subject to the statutory annual safety inspection.

Escape from heights within 10 seconds

The Evacuator® escape descent system is a life-saving device for high-altitude emergencies. It allows anyone to descend safely and quickly from heights up to 300 meters, in just 10 seconds.

Designed to save the lives at heights ranging up to 300 meters, the Evacuator® escape descent system is the world’s fastest and most user-friendly, fire proof, collective descent system, click on and go!

This award winning system provides a quick, intuitive escape and descent solution for everybody in an emergency situation. It is suitable for installation on wind turbines, offshore substations, harbour cranes and other high rise structures.

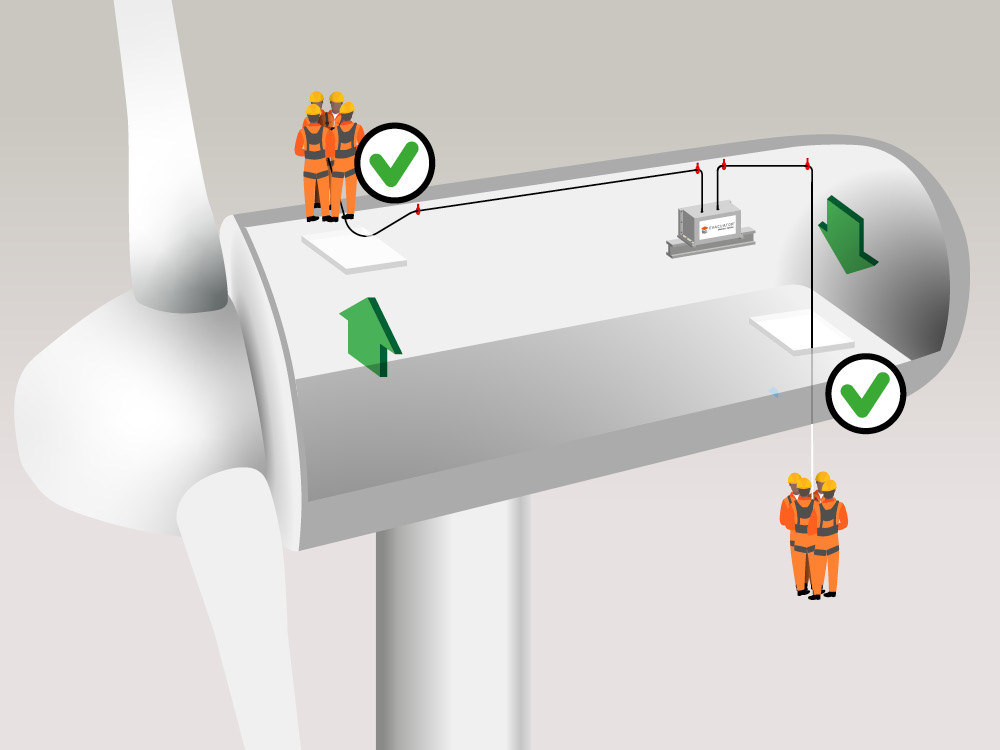

Windturbines

Onshore and offshore wind turbines

Offshore platforms

Oil or gas rigs, or offshore construction

Cranes

Container offloading, manufacturing, mining

High rise constructions

Safely evacuate people from high buildings

Simplicity is key

Step 1

Go to the emergency exit

Step 2

Connect harness onto Evacuator® escape-hook

Step 3

Start the descent

The fully automatic descent that follows has a descent speed of ±1 m/s

The EVACUATOR® is a device that can save lives in case of a fire. When a fire breaks out, people often feel scared and confused. They may not be able to act rationally or follow complex instructions. That’s why the EVACUATOR® is designed to be simple and easy to use. The device consists of a sturdy steel case that holds several reels with steel wires. If you want to learn more about how the EVACUATOR® can help you protect your staff and create a safer work environment, please contact us for more details.

Want to know more?

Looking to learn more about our innovative evacuation solution? Or do you want more details and personalized assistance, don’t hesitate to contact us!