Complete Wind Turbine Inspection

With a complete wind turbine inspection, all components of the turbine are inspected and issues are detected before they lead to alarms and loss of production. Besides complete turbine inspections, TeSuCon can also inspect specific parts in great detail.

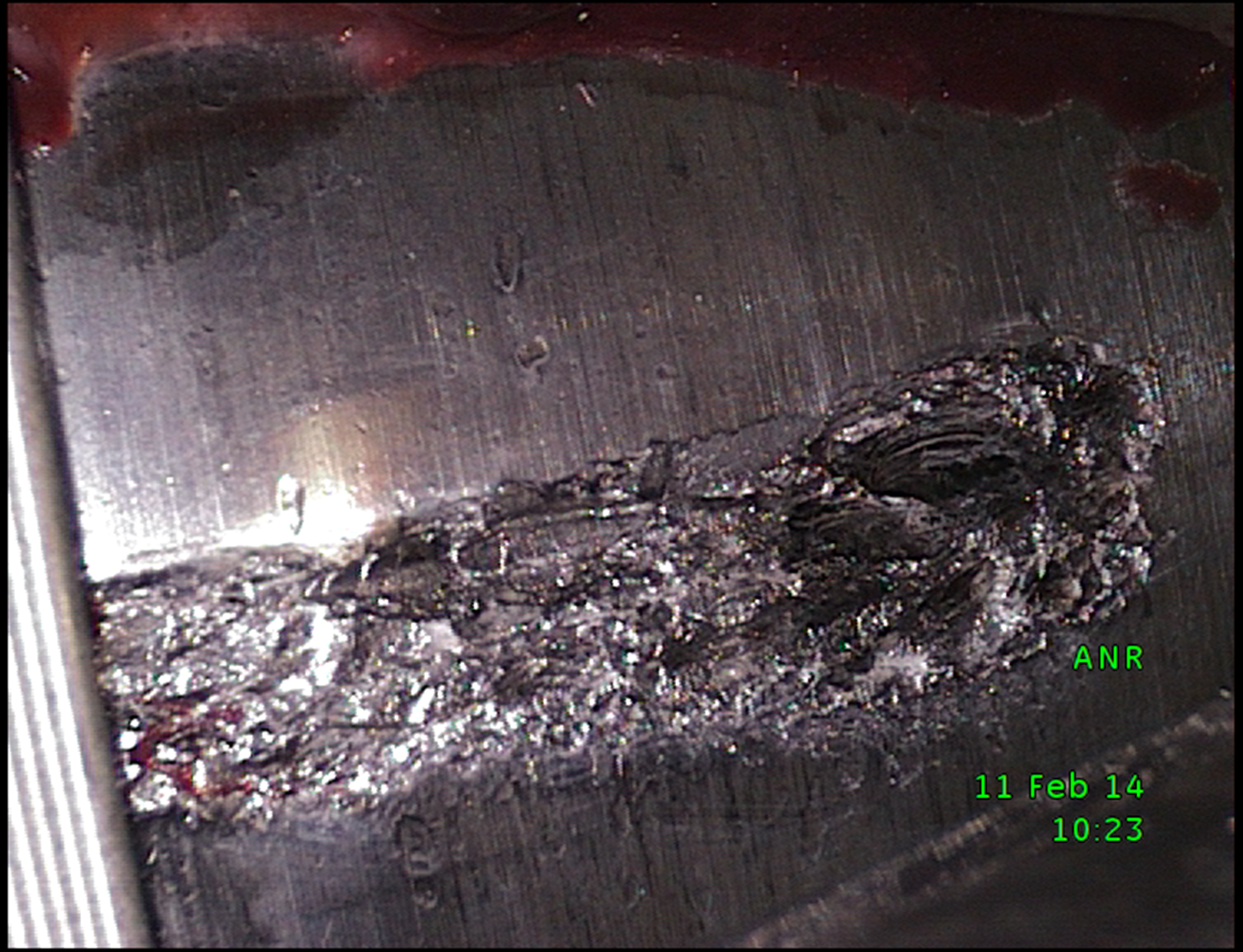

Blade Inspection

Large damage at the surface of the blade easily detected by a high-end SLR-camera in combination with a powerful telelens.

For a complete and thorough inspection, it is necessary to bring the specialist to the blade. Proper inspection of the lightning conductors and signs of delamination and osmose can only be conducted when the specialist can work on the blade. The best inspection results are obtained by using an Aerial Work Platform (cherrypicker) or with Suspended Access Equipment (skylifts ).

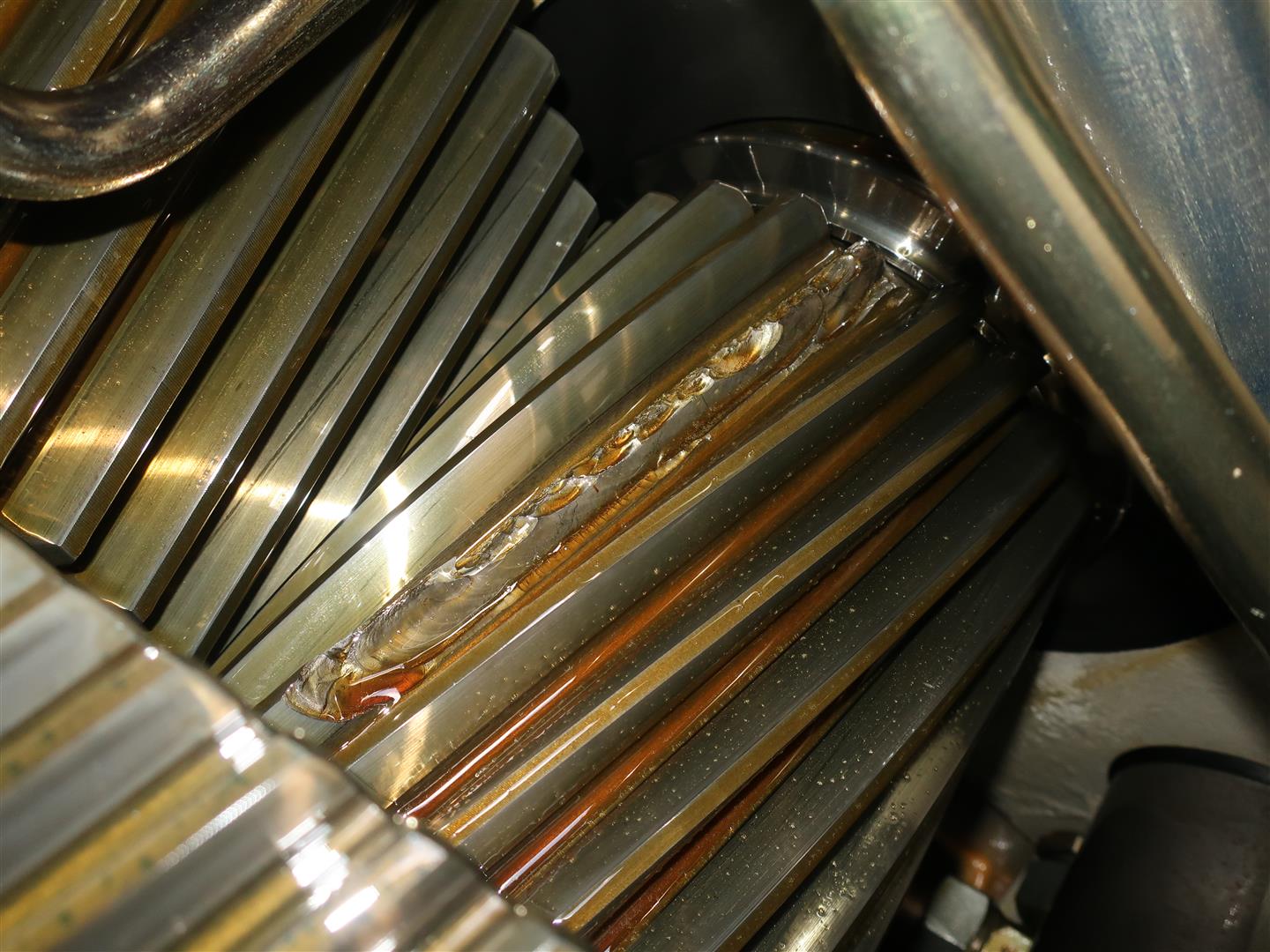

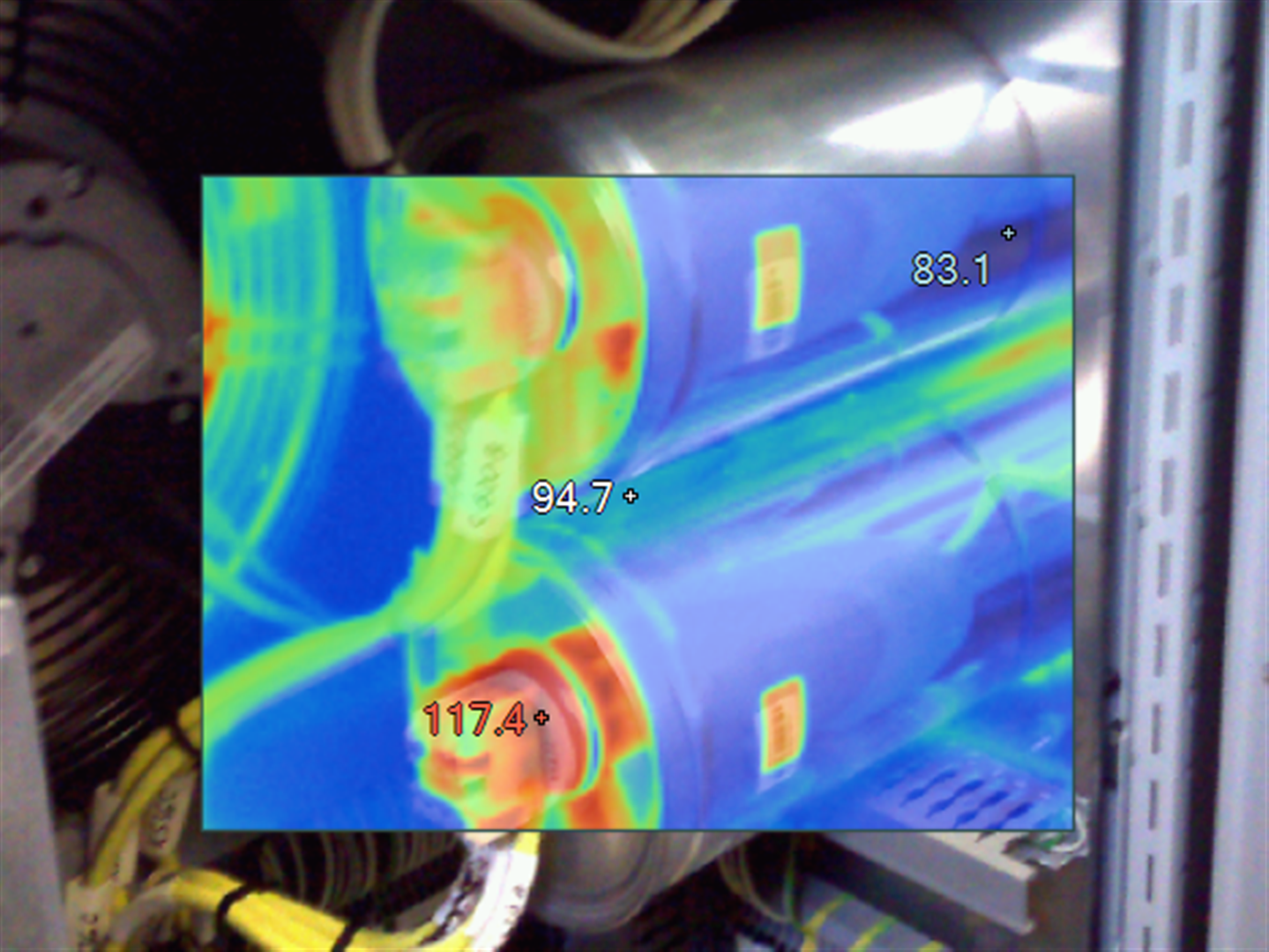

Electrical Inspections

All personnel at TeSuCon is qualified to work on electrical installations and trained in the safety rules as stated in NEN3140 and NEN3840.

By obeying the safety rules, important electrical components, such as main contactors and high-voltage transformers, can be inspected safely.